Martensitic Stainless Steel Stress Corrosion Cracking Mechanism

- 17 Comments!

Stainless steels obtain. This oxide film has so few defects that oxygen cannot easily diffuse through.

EXECUTIVE SUMMARY Objectives Chloride stress corrosion cracking (CLSCC) is one of the most common reasons why austenitic stainless steel pipework and vessels. ATLAS STEELS Stainless Steel Grade Selection Page 4 www.atlassteels.com.au Selection for Mechanical and Physical Properties High strength martensitic(e.g.

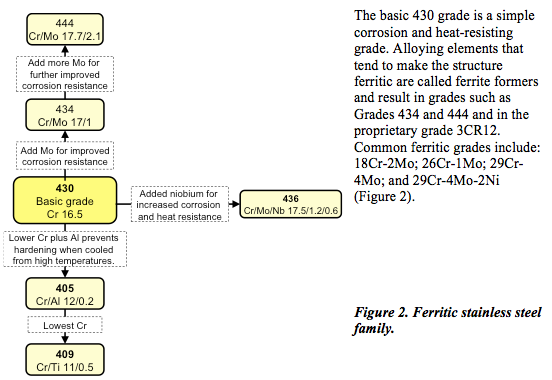

The oxide establishes on the surface and heals itself in the presence of oxygen. Some other alloying elements are often added to enhance specific characteristics. They include nickel, molybdenum, copper, titanium, aluminum, silicon, niobium, and nitrogen. They are. ferromagnetic, hardenable by heat treatments, and are usually less resistant to corrosion than some other grades of stainless steel. Excess carbides may be present to enhance wear resistance. Ferritic stainless steels are chromium containing alloys with Ferritic, body centered cubic (bcc) crystal structures.

Chromium content is typically less than 3. Austenite is formed through the generous use of austenitizing elements such as nickel. Chromium content typically is in the range of 1. The percentage each phase is a dependent on the composition and heat treatment. Most Duplex. stainless steels are intended to contain around equal amounts of ferrite and austenite phases in the annealed condition.

- SUBJECT: Corrossion problems associated with stainless steel 4-1. The rotating equipment business uses a great deal of 300 series stainless steel, and as a result we.

- 3 PRODUCT DESCRIPTION AK Steel 17-4 PH is a martensitic precipitation-harden-ing stainless steel that provides an outstanding combi-nation of high strength, good.

- SBB's steel glossary is great for finding the definition for any steel term associated to the industry.

Some compositions of stainless steel are prone to intergranular corrosion. When heated to around 700 °C, chromium carbide forms at the intergranular boundaries.

The primary alloying elements are chromium and nickel. Precipitation- hardening stainless steels may be either austenitic or martensitic in the annealed condition.

Raabe. Suppression of twinning and phase transformation in an ultrafine grained 2 GPa strong metastable austenitic steel: Experiment and simulation. Acta Materialia 9. UFG stainl. Uniaxial tensile testing at room temperature reveals an extremely high yield strength of 1. A crystal plasticity finite element model incorporating a constitutive law reflecting the grain size- controlled dislocation slip and deformation. Comparison of simulation and experiment shows that the deformation of ultrafine- grained 3.

Characterization of the Microstructure, Crystallographic Texture and Segregation of an As- cast Duplex Stainless Steel Slab. C. Raabe, steel research int. No. 6, page 4. 82, Characterization of the Microstructure, Crystallographic Texture and Segregation of an As- cast Duplex Stainless Steel Slab. Herrera et al - steel research int. DSSs have shown an excellent combination of resistance to general and localized.

Ni and Mo . DSSs are used in oil, gas, paper, desalination and petrochemical industries. The main process steps in the industrial manufacturing of duplex stainless steel sheets are continuous casting, slab reheating, hot rolling, coiling, hot band heat treatment, cold rolling and final.

Particular attention during manufacturing of these steels has to be paid to the forming steps at high temperatures. Hot working of steels with two phases may cause. The ductility depends on different. Moreover, it is affected by the different softening mechanisms in ferrite and austenite . Duplex stainless steels solidify by forming primary ferrite with austenite precipitates either from the liquid or in the solid state during cooling. The amount of austenite and.

At increased cooling rate the amount of austenite is reduced . Grains that have been formed by a . These orientation relationships can be described as a rotation of an angle . The slab. showed different macrostructures through the thickness.

The macrostructure can be divided into 3 types: fine equiaxed, columnar and coarse equiaxed grains. In all three regions, the volume fraction. The austenite has Kurdjumov- Sachs or Nishiyama- Wassermann relationship with the delta- ferrite. The. slab does not show a strong segregation profile through the thickness. The delta- ferrite is enriched in Cr and Mo, while austenite is enriched in Ni and Mn. Particle Stimulated Nucleation in Coarse- Grained Ferritic Stainless Steel.

Particle- stimulated nucleation (PSN) is investigated in Nb- containing ferritic stainless steel. Coarse- grained sheets were cold rolled to 8. K to 9. 98 K (7. PSN- ferritic- steels- 2.

METALL- TRANS- A- . Raabe, Design of a novel Mn- based 1 GPa duplex stainless TRIP steel with 6. Herrera Ponge Raabe Acta Materialia 5. The new alloy class proposed in this work uses Mn, C, and N (instead of only Ni) to stabilize the. Fe–1. 9. 9. Cr–0. Ni–0. 1. 6N–4. 7.

Mn–0. 1. 1C–0. 4. Cu–0. 3. 5Si, wt.%) . Our design strategy aims at an alloying corridor to obtain optimum austenite stability. The. motivation for that is twofold. First, the austenite should be sufficiently unstable that a transformation- induced plasticity (TRIP) effect is initiated upon loading.

Second, the. austenite should be sufficiently stable that the TRIP effect occurs over a wide strain regime, specifically at high strains, where strain hardening reserves are usually more desirable. The TRIP mechanism is based on deformation- stimulated displacive transformation of metastable austenite (face centered cubic Fe–Mn–N–C phase) to martensite (metastable or body. In the new alloy concept Mn not only replaces Ni. C and N, which promote austenite stabilization and provide additional solid solution strengthening . N also enhances. the resistance to localized corrosion and delays sensitization . Commercial grade lean DSS (LDX 2. Fe–2. 2Cr–4. Ni–0.

N–0. 0. 3C–0. 3. Mo, wt.%) exhibit a total elongation of up to 3. MPa (Fig. As well as these alloys with their limited.

DSS alloys . These Ni- free alloys. MPa, respectively, at an elongation to fracture of 4. The materials exhibited excellent resistance to stress corrosion cracking (SCC). Wessman et al. They found that the pitting corrosion resistance for the low and. Ni- free alloys decreased while the yield stress and tensile stress increased with higher N and.

Mn contents. The effect of Ni on the mechanical properties was not significant. Here, we report on the microstructure, texture and deformation mechanisms of a novel ductile lean duplex stainless steel (Fe–1. Cr–0. 4. 2Ni–0. 1. Adobe Photoshop Extended Working Keygen And Crack Rar Passwords. N–4. 7. 9Mn–0. 1. C–0. 4. 6Cu–0. 3.

Si, wt.%). The austenite is. Mn, C, and N (instead of Ni). Microsoft Sql Server Slow Query. The microstructure is characterized by electron channeling contrast imaging (ECCI) for dislocation mapping and electron backscattering diffraction. EBSD) for texture and phase mapping. The material has 1 GPa ultimate tensile strength and an elongation to fracture of above 6. Themechanical behavior is interpreted in terms of the strength of both the starting phases, austenite and ferrite, and the amount, dispersion, and transformation kinetics of the mechanically.

TRIP effect). Transformation proceeds from austenite to hexagonal martensite to near cubic martensite). The epsilon- martensite forms in the austenite with an orientation.

Shoji- Nishiyama. The alpha- martensite nucleates at the intersections of deformation bands, especially e- bands, with Kurdjumov–Sachs and Nishiyama–Wassermann relationships. Raabe. Acta Materialia 5. Cr Mn dup. The austenite is. Mn, C, and N (instead of Ni). The microstructure is characterized by electron channeling contrast imaging (ECCI) for dislocation mapping and electron backscattering diffraction (EBSD).

The material has 1 GPa ultimate tensile strength and an elongation to fracture of above 6. The mechanical behavior is interpreted in terms of the strength of both the. TRIP effect). Advances in the Optimization of Thin Strip Cast Austenitic 3. Stainless Steelsteel research int. No. 6 pages 4. 40 ff. Advances in the Optimization of Thin Strip Cast Austenitic 3.

Stainless Steel. D. Degenhardt, R. Sachtleber, L.

Ernenputschsteel research int. Thin strip steel casters offer a competitive. Today’s advanced twin roll thin strip casters for the production of stainless.

Twin roll thin strip casting of steels thus eliminates major steps required in conventional production, for instance slab handling, slab reheating, hot strip roughening / break- down. Figure 2). Both thin strip cast material and conventionally produced hot strips can be further. Thin strip casting of stainless austenitic steel (AISI 3. First, the thin. strip casting method permits the entire continuous conventional hot rolling process to be bypassed. The thin strip casting method is even capable of producing strips with a smaller thickness than.