Ford Ranger Remote Starter Installation

- 14 Comments!

Ford V8 to the Ford Bronco II, Ranger Truck 4 & 5 speed, adapter plate kit. Ford V8 engine conversions into Bronco IIs, Ranger pickups & Explorers have become very popular. Since pioneering conversions for these vehicles well over 2. The parts we manufacture are available for small block Ford V8s retrofitting stock engines, while keeping the stock transmission or installing a new transmission.

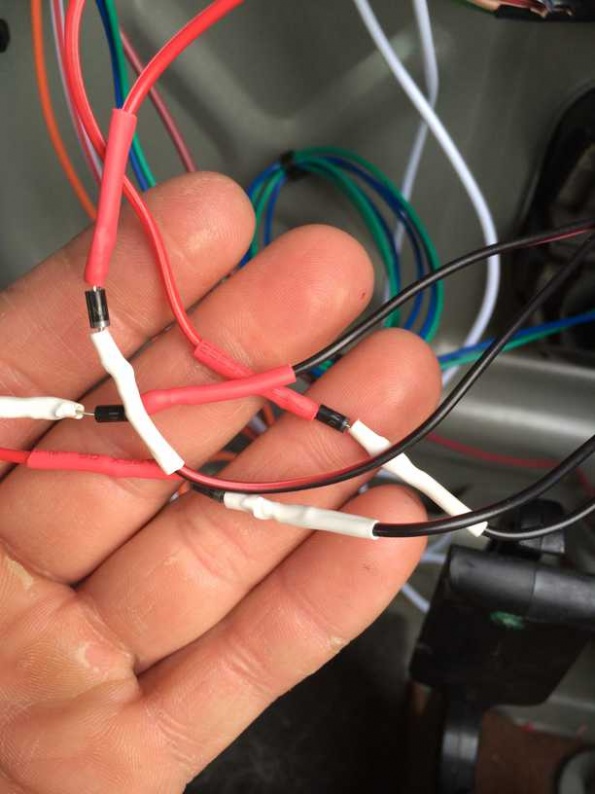

Ford Ranger V-8 engine swaps at The Ranger Station. Your top source for keyless remotes, key fob replacements, transponder key, and vehicle remote keyless entry keys for top vehicle brands. All the Ford parts and accessories you need are online at Auto Parts Warehouse. Get up to 70% off on retail prices! Free Shipping when you order over $50. Isolating Second Starter Wire for Remote Car Starter Installation.

Because of the diversity of applications, we do not offer complete conversion packages. We have grouped the conversion components by application. Many of our components are necessary when converting your engine and/or transmission. Items such as exhaust and radiators can be modified or sourced elsewhere.

- We offer an entire array of discount Ford accessories to help you customize your Ford or Lincoln. You can find any Ford accessory from floor mats to running boards.

- 712541 : Ford V8 to the Ford Bronco II, Ranger Truck 4 & 5 speed, adapter plate kit.

- Ford V8 engine conversions into Bronco Ils, Ranger pickups& Explorers have become very popular. Advance Adapters has been pioneering, conversions for these vehicles.

- Ideally, remote starters should be installed by a qualified technician because improper installation can damage.

- How to Choose a Remote Car Starter. Buying a remote car starter can be an overwhelming experience if you don't know what you're looking for. How should you choose a.

- Ford wire information, wire info, wiring information, wiring info, color codes, Technical Wiring Diagrams.

GENERAL CONVERSION INFORMATION: The Rangers & Bronco IIs were first introduced in 1. V6 or 4 cylinder.

They later came equipped with a 2. L, 3. 0. L or 4. 0. Update Word To Read Docx For Mac more. L V6 engine. Ford used various transmissions. The manual transmissions consisted of the Toyo Koygo, Mitsubishi or Mazda.

These transmissions are all light- duty 4 & 5 speeds. The automatics that Ford used were the C3, C5 and A4. LD. The conversion components we manufacture fit all Bronco II & Rangers. Currently, engine conversions using our components have been performed on Ranger pickups as new as 1.

Vehicles 1. 99. 8 & newer had frame rail and suspension changes in which our components do not fit. This vehicle came stock with a 4. L V6, and the A4. LD transmission. The adapters we manufacture fit Explorers 1.

Many questions arise when considering any engine swap and/or transmission swap. Some of these questions include what year & size block to use, transmission choice, transfer case & axle strength, suspension requirements, body lift, cooling, exhaust, etc. We’ve tried to address as many of these questions as possible. TOOLS REQUIRED: These vehicles utilize most metric fasteners. The engine is from Germany and the transmission is from Japan.

Therefore, it is suggested that before you begin your conversion you should obtain the proper metric wrenches to ease the removal and installation of your new engine and transmission. In addition to these tools, you will need an engine hoist and torque wrench, and the capability to drill 1/2. These conversions can be accomplished without welding or cutting; however, in some cases modifications may be required.

We recommend that the individual Ford shop manuals be obtained for torquing and electronic wiring specifications. ENGINE SELECTIONS: First check your local Department of Motor Vehicles for smog & engine requirements. Certain states (such as California) require the same year or newer engine as the vehicle. The engine should be complete, retaining all smog equipment. The most recommended engine is the Ford 3.

If your engine choice is a 3. Windsor, extra consideration should be given regarding exhaust clearance. A special oil pan must also be purchased. Ford 2. 89 V8 Engines Seldom used Ford 3.

V8 Engines Most popular. Ford 3. 51. W V8 Engines Difficult (oil pan & exhaust problems must be considered)Ford 3. M & 4. 00 Not available. Ford 4. 29 or 4. 60 Engines Not available Bronco II, Ranger Trucks & Explorer Swap Information. ENGINE & TRANSMISSION REMOVAL STEPS: To remove the engine, take off the hood, drain the cooling system and depressurize the A/C system.

Next, disconnect all necessary electrical connections and remove the fan shroud, radiator, and fan. Make sure that you label all of the electrical connections to ensure proper identification for the new engine. The next step is to remove the heater hoses, air cleaner, vacuum hoses, throttle cable, and the upper .

It is advised that you label all of your vacuum hoses so that they can be reattached in the correct location. Now, remove the fuel lines and the transmission strut rods and, finally, the motor mount bolts. In some instances, it will be necessary to remove the A/C compressor and the power steering pump; however, in most applications this can be avoided.

This procedure for removing the engine will take between two and six hours. The transmission should be removed prior to the removal of the engine.

WD ENGINE MOUNTS: On 4. WD vehicles, the original 4 cylinder and V6 engines are supported by a large metal crossmember that provides the necessary engine mount positions.

When converting to the new V8 engine, you will eliminate the original engine mounting pads. You will be required to drill two new 1/2. The instruction sheet for these mounts provides measurements for the new hole locations. Our 4. WD engine mounts, PN7. V8 engine and the existing crossmember. They will position the engine so that no additional oil pan modifications will be required when using the regular Ford dual sump pan.

WD ENGINE MOUNTS: On 2. WD vehicles, the original 4 cylinder and V6 engines are supported by a large metal crossmember that provides the necessary engine mount positions.

These mounts are designed to fit both body styles of the Ford Ranger 2. WD pickups. The mounts are slotted to have some adjustment to the engine position once installed.

On the early body style Ranger, the driver's side mount will require a hole to be drilled in the cradle. Accounting for just a couple of differences, the installation of these mounts into both the early and late model Rangers are basically the same.

Rangers 1. 99. 2 & earlier require a 1/2” hole to be drilled into the stock engine cradle for the installation of our mounts. It also requires the fuel filter to be relocated. The fuel filter is located inside the driver's side frame rail. The fuel filter must be relocated to allow for proper exhaust clearance.

On both body styles of the Rangers, we recommend doing a . The mounts should be installed loosely into the Ranger engine cradle. Lower the block into position on top of the new mounts and adjust the block to the furthest forward location allowed by the slots in the mounts. Adjust the block so that it sets level from side- to- side.

This first trial run will allow you to mark the air box on the passenger side of the vehicle for proper clearance. The driver's side firewall will also require a slight amount of clearance (a small dent in the firewall to obtain valve cover and head clearance).

Remove the engine and perform the necessary modifications to the air box and the firewall. Our engine mounts are PN7. A. The Ford V8 engine rubbers mounts are Part No. E4. TZ- 6. 03. 8G, or AA PN7. On 2. WD conversions, you will have the option of using any transmission originally hooked to a V8 engine. The output shaft on 2. WD V8 transmissions are normally 2.

Bronco II, Ranger & Explorer 2. WD transmission. As a general rule, the back of the new V8 engine is located exactly in the same position as the back of the original V6 or 4 cylinder engine. If you obtain a 2.

WD transmission approximately the same length as the original transmission, then you will not have to modify your drivelines. In other words, if your 5 speed transmission is 2. On some applications, the transmission side of the driveshaft may have to have the yoke changed. AXLE STRENGTH: Your vehicle is equipped with one of three different rear axles Ford used. Up to 1. 98. 4, Ford used a 6.

This axle is marginal up against a V8. Vehicles 1. 98. 5 to 1. These axles are usually sufficient to handle the power of a V8.

Something to consider is tire size. If a large tire size is going to be used and the V8 is a high horsepower application, you might consider having a custom rear end built. WATER PUMP: There are two different belt systems used on Ford V8s; either a “V” belt or a Serpentine. The water pumps must have the fluid exit on the driver’s side if you are planning to use our radiator. Most water pumps have this configuration. The Serpentine pumps are a reverse rotation water pump. The stock belt system must be retained on this water pump.

Either pump can be used with a new engine swap; however, we have found that you can obtain more engine clearance with the “V” belt system.